Dans les systèmes d'automatisation logistique modernes, la chaîne de convoyage de caisses CC600 d'Amsterdam joue un rôle crucial. Avec le développement constant des technologies d'entreposage et de tri, les entreprises ont des exigences de plus en plus élevées en matière de stabilité, d'efficacité et de…

Spécifications

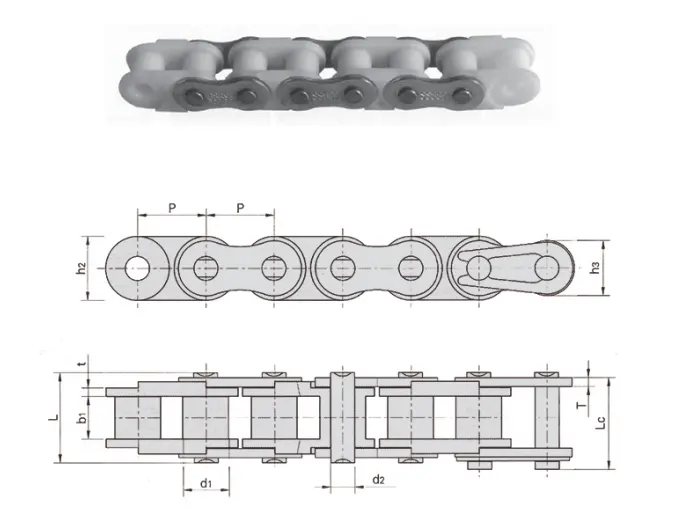

This 16ASpaSS Stainless Steel Engineering Plastic Combination Chains is equipped with the following specifications:

| Chaîne No. |

Emplacement | Diamètre du rouleau | Largeur jusqu'à XNUMX fois plaques intérieures |

Pin diamètre |

Pin longueur |

Pin longueur |

Inner plaque profondeur |

avant épaisseur |

UItime élastique force |

|

| P | d1 (max) | bl(min) | d2 (max) | L (max) | Lc (max) | h2 (max) | h3 (max) | T (max) | Q (min) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN / LB | |

| 04CSPaSS | 6.35 | 3.3 | 3.1 | 2.31 | 7.9 | 8.4 | 6 | 5.06 | 0.8 | 0.42/95.2 |

| 06CSPaSS | 9.525 | 5.08 | 4.68 | 3.58 | 12.4 | 13.2 | 9 | 7.8 | 1.3 | 0.77/175 |

| 08ASPaSS | 12.7 | 7.92 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 10.4 | 1.5 | 1.75/397.6 |

| 10ASPaSS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.1 | 13 | 2.03 | 2.45/556.5 |

| 12ASpass | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 15.6 | 2.42 | 3.15/716 |

| 16ASpass | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 20.5 | 3.25 | 5.25/716.1 |

| 08BSPaSS | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 10.6 | 1,60 | 1.75/397.6 |

| 10BSPaSS | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 13.7 | 1.7 | 2.45/556.5 |

| 12BPaSS | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 15 | 1.85 | 2.94/716.1 |

| 16BPaSS | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 21 | 4.15/3.1 | 5.25/716.1 |

Introduction

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains represent a high-quality and innovative solution extensively utilized across various sectors. Crafted from stainless steel and engineering plastic, these chains guarantee durability and strength. They are engineered to perform reliably and efficiently, even in challenging conditions. The chains feature exceptional benefits, such as high load capacity, corrosion resistance, and low friction, making them perfect for heavy-duty applications.

Conception et construction

The unique design and construction of the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains distinguish them from typical chains. Utilizing premium stainless steel and engineering plastic, these chains are both robust and durable. They are available in a variety of sizes and lengths to suit the specific requirements of diverse applications. Additionally, they are constructed with precision to ensure optimal operation.

Caractéristiques et avantages

Capacité de charge élevée

A prominent advantage of the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains is their exceptional load capacity. They are capable of handling substantial loads without risk of breaking, making them ideal for demanding applications.

Résistance à la corrosion

Built with high-grade stainless steel, these chains boast excellent resistance to corrosion. They can endure harsh environmental conditions, including exposure to chemicals or saltwater, without succumbing to rust or degradation.

Faible frottement

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains possess a low friction coefficient, making them suitable for environments where reduced friction is critical. They function smoothly and efficiently, minimizing wear on both the chains and accompanying components.

Longue vie de service

Designed for longevity, these chains are constructed with durable materials, allowing them to endure years of heavy use without the need for frequent repairs or replacements.

Applications

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains find extensive applications across various industries. Commonly used in food processing, packaging, material handling, and automotive sectors, they are also effective in harsh environments, such as offshore drilling platforms and mining operations.

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains are a high-quality, innovative choice, providing numerous advantages. They are tailored for reliable performance in heavy-duty situations, constructed from top-tier materials that ensure their strength and durability. Suitable for a range of industries and adverse environments, these chains represent an excellent option for those seeking high-performance solutions.

Pourquoi choisir nos chaînes à rouleaux en acier inoxydable ?

RP Techniek BV serves as the official sales representative for Ever-power Group in the Netherlands. We take pride in our partnership with this reputable company and are dedicated to delivering their premium products to our clients.

Among our key products is the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains, meticulously designed for durability and precision, making them suitable for various industrial applications.

What differentiates us is our unwavering commitment to exceptional product quality and superior service. Our stainless steel roller chains are produced using the highest quality materials and the latest manufacturing technology, ensuring reliability and durability.

In addition to our exclusive product line, we offer a comprehensive selection of stainless steel roller chains to meet diverse customer requirements, providing a wide array of choices.

To illustrate our capabilities, below is an image showcasing our manufacturing strength:

Pignons à vendre

For those seeking suitable sprockets for engineering applications, the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains present an excellent starting point. Renowned for their durability and corrosion resistance, this chain type is well-suited for numerous uses.

Selecting the appropriate sprockets to complement your 16ASpaSS chain is essential for optimal performance and longevity. Our company provides a range of sprockets, including options made from stainless steel, carbon steel, and various other materials, available in different sizes and tooth counts to meet specific requirements.

Whether you need standard or customized sprockets, we have a solution that suits your needs. Our expert team is ready to assist you in choosing the ideal sprockets for your applications to ensure reliability and peak performance.

To explore our sprocket offerings, please reach out to us today. We look forward to collaborating with you to find the perfect solution for your engineering needs.

Informations Techniques

| Éditeur |

Zqq |

|---|

Blogs mis à jour

Structure et caractéristiques de conception des pignons des convoyeurs à raclettes

Cet article explique et analyse principalement les caractéristiques de conception structurelle du pignon en fonction de son rôle dans le convoyeur à raclettes, ce qui conduit à la nécessité de rechercher le matériau et la technologie de traitement du pignon et les aspects techniques clés...

Normes de mise au rebut et de remplacement des pignons de levage des palans électriques à chaîne

La mise au rebut et le remplacement du pignon de levage du palan à chaîne constituent un enjeu de sécurité majeur. Le pignon de levage est un composant essentiel du palan électrique. Une fois hors d'usage, il doit être remplacé rapidement afin de garantir...