Dans les systèmes d'automatisation logistique modernes, la chaîne de convoyage de caisses CC600 d'Amsterdam joue un rôle crucial. Avec le développement constant des technologies d'entreposage et de tri, les entreprises ont des exigences de plus en plus élevées en matière de stabilité, d'efficacité et de…

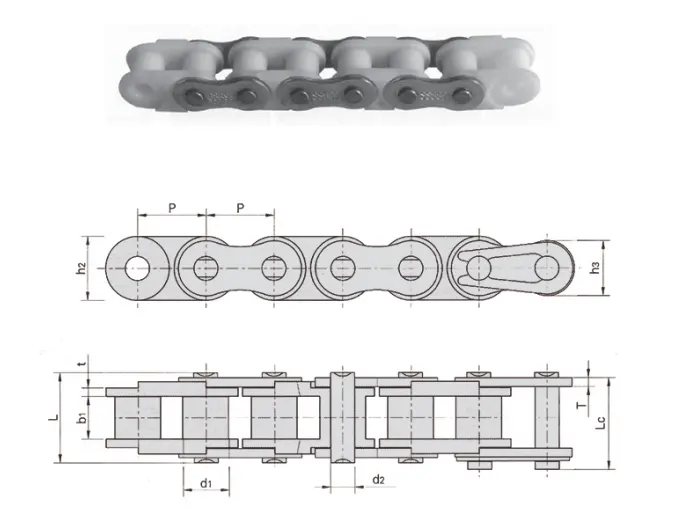

Spécifications des chaînes combinées en acier inoxydable et plastique technique 12ASpaSS

- Matériau : acier inoxydable et plastique technique

- Type de chaîne : Chaînes combinées

- Numéro de modèle : 12ASpaSS

- Taille : varie selon le numéro de modèle

- Tension maximale autorisée : varie selon le numéro de modèle

- Plage de température de fonctionnement: -40 ° C à 90 ° C

- Résistance à la corrosion : élevée

- Résistance chimique : Excellente

| Chaîne No. |

Emplacement | Diamètre du rouleau | Largeur jusqu'à XNUMX fois plaques intérieures |

Pin diamètre |

Pin longueur |

Pin longueur |

Inner plaque profondeur |

avant épaisseur |

ULTIME élastique force |

|

| P | d1 (max) | bl(min) | d2 (max) | L (max) | Lc (max) | h2 (max) | h3 (max) | T (max) | Q (min) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN / LB | |

| 04CSPaSS | 6.35 | 3.3 | 3.1 | 2.31 | 7.9 | 8.4 | 6 | 5.06 | 0.8 | 0.42/95.2 |

| 06CSPaSS | 9.525 | 5.08 | 4.68 | 3.58 | 12.4 | 13.2 | 9 | 7.8 | 1.3 | 0.77/175 |

| 08ASPaSS | 12.7 | 7.92 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 10.4 | 1.5 | 1.75/397.6 |

| 10ASPaSS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.1 | 13 | 2.03 | 2.45/556.5 |

| 12ASpass | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 15.6 | 2.42 | 3.15/716 |

| 16ASpass | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 20.5 | 3.25 | 5.25/716.1 |

| 08BSPaSS | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 10.6 | 1.60 | 1.75/397.6 |

| 10BSPaSS | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 13.7 | 1.7 | 2.45/556.5 |

| 12BPaSS | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 15 | 1.85 | 2.94/716.1 |

| 16BPaSS | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 21 | 4.15/3.1 | 5.25/716.1 |

1. Introduction

This article delves into the advanced features and uses of the 12ASpaSS Stainless Steel Engineering Plastic Combination Chains. Designed to deliver exceptional durability and adaptability, these chains are ideal for a range of industrial applications.

2. Résistance et résistance à la corrosion améliorées

The 12ASpaSS Stainless Steel Engineering Plastic Combination Chains are crafted from a specialized blend of stainless steel and top-grade engineering plastic. This unique combination provides remarkable strength and outstanding corrosion resistance, even in challenging environments. These chains are capable of enduring extreme temperatures, chemicals, and humidity, which makes them suitable for various applications.

3. Fonctionnement fluide et silencieux

Thanks to precise engineering and state-of-the-art manufacturing processes, the 12ASpaSS Combination Chains ensure smooth and silent operation. The incorporation of engineering plastic in the chain design minimizes friction and noise, facilitating a more seamless and efficient workflow. This characteristic is especially valuable in settings where noise reduction is critical, such as in food processing facilities or cleanrooms.

4. Conception légère et flexible

In contrast to conventional chains, the 12ASpaSS Combination Chains boast a lightweight and flexible structure. The use of engineering plastic components results in less weight, allowing for straightforward handling and installation. Additionally, their flexible design makes them adaptable to various applications, including conveyor systems, packaging machinery, and automation equipment.

5. Options personnalisables

To maximize versatility, the 12ASpaSS Combination Chains provide customizable options tailored to meet specific needs. Clients can select different chain lengths, widths, and attachment configurations, facilitating seamless integration into existing systems or the development of new setups designed for individual requirements.

In summary, the 12ASpaSS Stainless Steel Engineering Plastic Combination Chains are a dependable solution for sectors that demand robustness, adaptability, and efficiency. Their distinctive construction, superior strength, quiet operation, lightweight design, and customizable options make them an excellent choice for a variety of industrial applications.

Pourquoi choisir nos chaînes à rouleaux en acier inoxydable ?

RP Techniek BV acts as the sales agent for Ever-power Group in the Netherlands. Representing this respected group, we provide a diverse selection of stainless steel roller chains, including the highly dependable 12ASpaSS Stainless Steel Engineering Plastic Combination Chains.

Our company is distinguished by several unique selling propositions that differentiate us from our competitors. Foremost, we emphasize the quality of our products. Our stainless steel roller chains are designed to endure even the most extreme environments, ensuring long-lasting durability.

In addition to our superior product quality, we prioritize exceptional customer service. Our dedicated staff is committed to delivering prompt and effective support to fulfill all our customers' needs. We believe in fostering strong relationships with our clients and consistently aim to surpass their expectations.

Moreover, we take pride in our robust manufacturing capabilities. Equipped with cutting-edge facilities and advanced technology, we can produce stainless steel roller chains of various types and specifications to accommodate a wide range of industry requirements.

Beyond the 12ASpaSS Stainless Steel Engineering Plastic Combination Chains, we offer an extensive selection of other stainless steel roller chains. Whether you need corrosion-resistant options, high load capacity, or specific measurements, we have the optimal solution for your application.

Pignons à vendre

For the perfect pairing with the 12ASpaSS Stainless Steel Engineering Plastic Combination Chains, our company has a wide array of sprockets available to meet your needs.

Our sprockets are crafted with precision and made from high-quality materials, ensuring durability and reliable performance. Whether you require a small sprocket for light-duty use or a larger option for heavy-duty machinery, we have the right solutions for you.

From standard tooth profiles to customized designs, we can supply you with the ideal sprocket to suit your specific requirements. Our sprockets come in various sizes, tooth counts, and materials, including stainless steel, cast iron, and engineering plastics.

With our extensive assortment of sprockets, you can trust that we have the perfect fit for your needs. Reach out to us today to explore our comprehensive selection of sprockets for sale.

Informations Techniques

| Éditeur |

Zqq |

|---|

Blogs mis à jour

Structure et caractéristiques de conception des pignons des convoyeurs à raclettes

Cet article explique et analyse principalement les caractéristiques de conception structurelle du pignon en fonction de son rôle dans le convoyeur à raclettes, ce qui conduit à la nécessité de rechercher le matériau et la technologie de traitement du pignon et les aspects techniques clés...

Normes de mise au rebut et de remplacement des pignons de levage des palans électriques à chaîne

La mise au rebut et le remplacement du pignon de levage du palan à chaîne constituent un enjeu de sécurité majeur. Le pignon de levage est un composant essentiel du palan électrique. Une fois hors d'usage, il doit être remplacé rapidement afin de garantir...